Blog

At LPS Bossard India, we manage thousands of fasteners and components daily across stores, quality labs, kitting areas, and dispatch zones. With such a high volume and variety, even a small mix-up or delay can lead to more significant downstream issues.

To stay efficient, safe, and delivery-ready, we follow one simple principle every day: Discipline in the workplace — powered by the 5S Methodology.

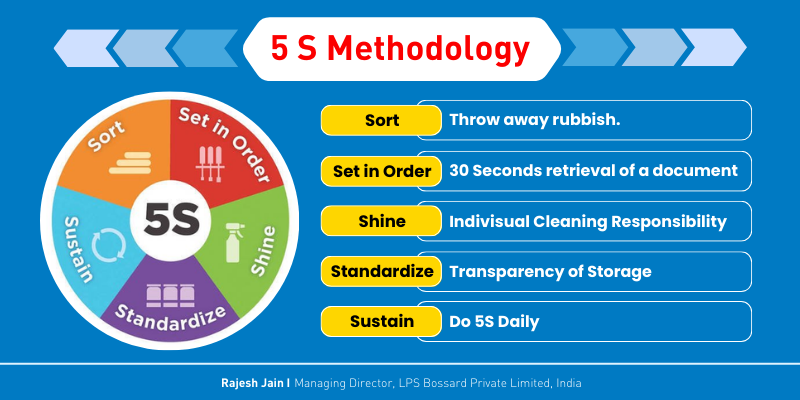

🔍 What is 5S?

The 5S system maintains a clean, organized, and efficient workspace. Here's how we implement each "S" — the LPS Bossard way:

🟡 Sort (Seiri)

Throw away rubbish.

We remove unused tools, expired labels, and unwanted packing material. Only essentials stay — everything else goes.

🟠 Set in Order (Seiton)

30 seconds retrieval of a document.

Every item has a designated place:

- Labeled racks and bins

- Tool boards with outlines

- Marked trolley stations

- Nothing is ever “missing” — it’s exactly where it should be.

🟢 Shine (Seiso)

Individual cleaning responsibility.

We clean our workspaces — every shift, every day.

Machines, tables, and even drawers are wiped down by the teams who use them.

🟣 Standardize (Seiketsu)

Transparency of storage.

- Clear SOP boards for kitting, dispatch, and inbound areas.

- Visual checklists are part of daily review meetings.

- Everyone knows the process and follows it.

🔵 Sustain (Shitsuke)

Do 5S daily.

The hardest S — but we make it routine:

- Daily checks by line leaders

- Monthly audits and feedback

- Floor-walk training for new joiners

- Department-wise 5S awards

📈 Benefits We’ve Seen

✅ Faster access to fasteners and tools, especially during peak hours

✅ Clearer stock movement — less searching, more doing

✅ Better coordination between departments

✅ Safer work areas — no spills or scattered tools

✅ Higher ownership — every team takes pride in their zone

🏆 Recognition through 5S Awards motivates teams to sustain these improvements and set new benchmarks.

🧠 More Than a System — A Way of Working

At LPS Bossard, 5S is not a one-time campaign. It’s a daily discipline, led by our teams and supported by leadership. No external consultants — just internal ownership. Like quality and safety, 5S is now part of our culture.